Wednesday 23 September 2015New Approach to Partnering

As we all face increased competition and the challenges of improving efficiency, it’s time to remodel our working relationships.

that there would soon be a significant step change in traditional working supplier/ customer relations -from bid and supply to one of collaboration and trust- you would have probably been laughed out the building, yet the winds of change are here.

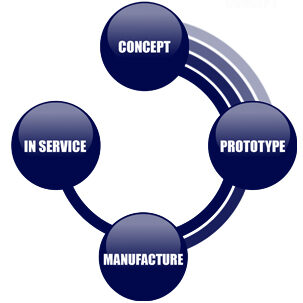

Nowadays we are seeing less of the “build to print” attitude and more of a partnership approach, which many of our customers (and potential customers) are looking to build upon. This cultural shift is the driving force of a closer collaboration that will ensure that each product moves from concept through to volume manufacturing with seamless efficiency.

Part of the challenge is to ensure that the product is robust in terms of component availability, lead times, manufacturability and that it also remains within a certain budget. This cultural step change allows all supply chain project partners have full clarity to ensure we achieve the best possible outcome, with no surprises.

Trust

Open and honest working relationships are simply the best way forward, given that they promote improved performance through collaborative business relationships based on best value, rather than lowest cost.

As customers understand the additional benefits of suppler/customer engagement, they quickly realise the added value each can bring to the table in terms of experience and production knowledge. This maximises joint effectiveness of both party’s resources and helps to

mutual trust. It also delivers security of supply and drives potential cost savings.

Many of our customers now involve us at the concept stage ensuring the product enters the market in a timely and cost effective manner, often with improvements or upgrades being applied at the preproduction stage.

Communications

Sharing of information is key, so too is communication with the customer at every level of the supply chain. This ensures all stakeholders are fully aware of the project status from sales forecast, lead time, stock holding and manufacturing status, thus reducing reaction times and helping to mitigate any risk.

Historically there has been a culture where all communications are made via email rather than talking. It seems that we are so busy trying to cover ourselves with audit trails that we are losing the ability to talk. Whilst modern communications may speed up the transfer of information, it’s also important to maintain personal contact which will save time prevent any misunderstandings and develop personal working relationships.

Cost effectiveness

As we are all aware, the cheapest price is not always the best option. As a customer you will quite rightly expect support with your product, transparency of costs and expectation of quality. Through partnering, contract awards are still subject to rigorous competition, but also judged on predetermined combinations of quality and cost. We have certainly adopted this as part of our business model and it has proven in the long run to improve our customer service.

Building on reputation

Partnering may not be a new concept and improving communication shouldn’t come as a surprise, however it is important to ensure that they form part an integral element of your future strategy. The benefits can not only develop the skills of your mutual teams, but also introduce a trusted and open working environment that improves and enhances the customer/supplier relationship.